Zinc Oxide 200nm EasyDisperse™

- Product Code: 248

Zinc Oxide Nano (200 nanometers) protects against both UVA/UVB, lightweight, does not contain oil. Doesn't clog pores. High security Can spread easily and completely

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

| Test Name | Specification |

|---|---|

| Appearance | White powder |

| Odor | Odorless or Faint odor |

| Loss on Drying | < 2.0% |

| Heavy Metal (ppm) - Pb | < 20 ppm |

| Heavy Metal (ppm) - As | < 3 ppm |

| pH | 8.00 ~ 11.00 |

| Hydrophobicity | To be floating on the distilled water for more than 1 hour |

| Microorganisms | 100 microorganisms/g No Pathogens |

| Particle Size (Average of 80%) | 150-250nm |

Zinc Oxide Zinc Oxide 200nm Particle EasyDisperse™ is Zinc Oxide powder that has been coated with Triethoxycaprylylsilane To be able to easily and completely disperse in silicone. For use as Physical Sunscreen and can be spread easily in powder. or oil For making makeup such as Mineral Makeup, Foundation Powder, Lipstick

EasyDisperse™ is different from ordinary Zinc Oxide in that it is easily and completely dispersed so that the Zinc Oxide particles are evenly distributed in the formula. Does not settle even though it is in a liquid sunscreen formula. Perfect distribution provides effective UVA/UVB protection.

Formulas that use Zinc Oxide should include 0.2-0.3% Xanthan Gum and 3-4% Propylene Glycol to help complete the dispersion of Zinc Oxide to ensure good formula stability.

Advantages of Physical Sunscreen: Less likely to clog pores than Chemical Sun Screen and is safer than Chemical Sun Screen because there are no ingredients that can be absorbed into the skin. Physical Sun Screen just covers the skin and protects it from UVA/UVB. Can hit the skin directly.

Disadvantages of Physical Sunscreen: Because it is a powder that conceals the skin, it does not allow UVA/UVB light to fall on the skin easily. Therefore, it often makes the skin shinier or shinier when used. The small particle size (nano particle) helps reduce this shine/shiny, but it still cannot compete with Chemical Sun Screen which does not cause shine/shiny.

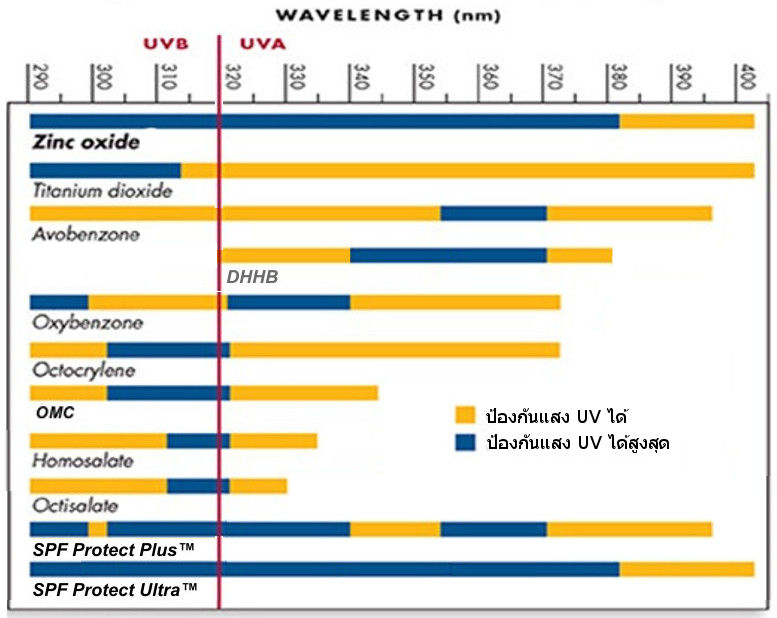

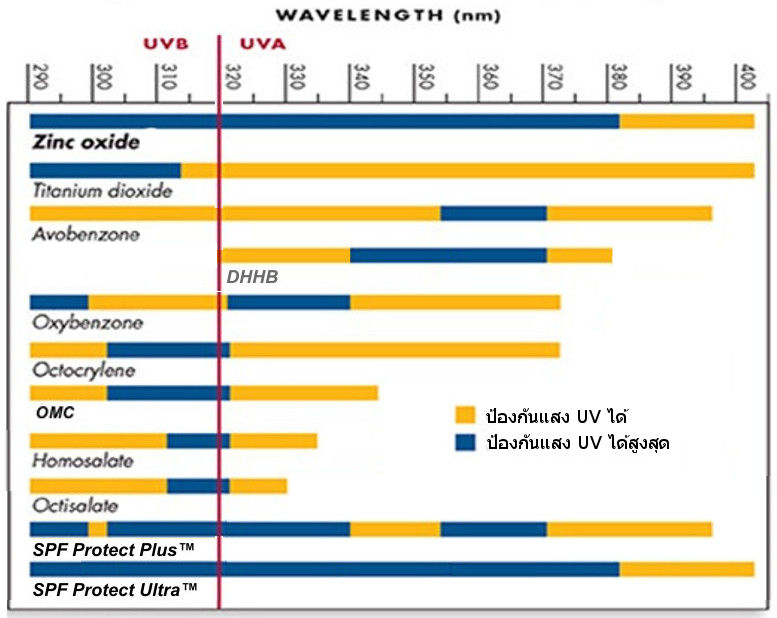

Difference Between Titanium Dioxide and Zinc Oxide: Both Ingredients It acts to protect against UV light in different wavelengths. Titanium Dioxide can protect against short-wave UVA and both short- and long-wavelength UVB, while Zinc Oxide can protect against long-wave UVA well. In mixing sunscreen formulas Therefore, both ingredients should be used. Because it can cover UVA/UVB at all wavelengths completely.

The company sells 4 types of Zinc Oxide.

1. Zinc Oxide 200nm EasyDisperse™, 200nm powder, silicone coated. Makes it easy to spread into any sunscreen formula. Gives a soft feeling on the skin, adheres well to the skin, and gives low whiteness.

2. Zinc Oxide Micronized powder type, uncoated, suitable for use in formulas with disinfectant effects such as deodorant formulas. Not suitable for use in sunscreen. that requires high dispersion to achieve good sun protection performance

3. Zinc Oxide 35nm Liquid, liquid type , with a powder particle size of 35 nanometers, ready to be mixed in any sunscreen formula, easy to use, feels soft on the skin, adheres well to the skin, does not cause whiteness on the skin.

4. Zinc Oxide Nano EasyDisperse™ Powder type smaller than 200nm, coated with silicone. Makes it easy to spread into any sunscreen formula. Gives a soft feeling on the skin, adheres well to the skin, and gives the lowest whiteness.

Recommendations for choosing to use in various products

Sun protection products who want to focus on sun protection efficiency And there is no need to cause whiteness on the skin. It is an emulsion in an oil-in-water system using Zinc Oxide Nano EasyDisperse™.

Sun protection products who want to focus on sun protection efficiency And does not have to cause whiteness on the skin by being an emulsion in a water-in-oil system using Zinc Oxide 35nm Liquid, liquid type.

Sun protection products who want to claim that it is non-nano Zinc Oxide, choose Zinc Oxide 200nm EasyDisperse™

Diaper rash products, deodorant or deodorant/odorant, or disinfectant, choose Zinc Oxide Micronized.

Usage rate: 5-25% (use according to desired efficiency Please see how to calculate SPF and PA above.)

Appearance: White powder, light weight, particle size 200nm on average.

Mixing: For sunscreen, mix in Cyclomethicone silicone in a 1:1 ratio (please see mixing instructions below for details). For powder makeup. Can be mixed directly with other types of flour.

Storage: Store at room temperature. Avoid sunlight. Shelf life: 2 years.

INCI: Zinc Oxide (97%), Triethoxycaprylylsilane (3%)

Please see how to mix sunscreen here.

*Other types of Zinc Oxide have different SPF values. Therefore, this formula cannot be used to calculate.

Be the first to review this product :-)

Recent dicussion threads:

- › 2023-11-20 Please ask for advice on sun protection formulas.

Example recipes using this ingredient:

- › lock_outlineSun Screen Lotion by Asmuni

- › lock_outlineWhitening Sunscreen By Cream Champa

- › lock_outlineSUNSCREEN MAKE UP BASE CREAM MOISTURIZING

- › lock_outlineSILKY SUNSCREEN MATTE FOUNDATION CREAM

- › lock_outlineUV SUN SILICONE CREAM

- › lock_outlineDD Watermelon SPF50 PA3

- › lock_outlineTHE DAYLIGHT ULTRA PROTECTION

- › lock_outlineCELLEBLANC PEARLA MORNING FILTERS

- › lock_outlineUV SUNSCREEN

- › lock_outlineLORDINAIRE PEARLA MORNING FILTERS

- › lock_outlineHybrid Sunscreen

- › lock_outlineDaycream by Emmaline

- › lock_outlineOTY Beauty BB Smooth Sunscreen SPF50 PA

Recommend Lab-Service

| Lab Service | Price |

|---|---|

| SPF UVA, UVB measurement service equipment (Boots Star/PA eq.)

Measurement of SPF/PA value on a finished product |

฿ 1,800.00 |

Zinc Oxide Nano (200 nanometers) protects against both UVA/UVB, lightweight, does not contain oil. Doesn't clog pores. High security Can spread easily and completely

Zinc Oxide Zinc Oxide 200nm Particle EasyDisperse™ is Zinc Oxide powder that has been coated with Triethoxycaprylylsilane To be able to easily and completely disperse in silicone. For use as Physical Sunscreen and can be spread easily in powder. or oil For making makeup such as Mineral Makeup, Foundation Powder, Lipstick

EasyDisperse™ is different from ordinary Zinc Oxide in that it is easily and completely dispersed so that the Zinc Oxide particles are evenly distributed in the formula. Does not settle even though it is in a liquid sunscreen formula. Perfect distribution provides effective UVA/UVB protection.

Formulas that use Zinc Oxide should include 0.2-0.3% Xanthan Gum and 3-4% Propylene Glycol to help complete the dispersion of Zinc Oxide to ensure good formula stability.

Advantages of Physical Sunscreen: Less likely to clog pores than Chemical Sun Screen and is safer than Chemical Sun Screen because there are no ingredients that can be absorbed into the skin. Physical Sun Screen just covers the skin and protects it from UVA/UVB. Can hit the skin directly.

Disadvantages of Physical Sunscreen: Because it is a powder that conceals the skin, it does not allow UVA/UVB light to fall on the skin easily. Therefore, it often makes the skin shinier or shinier when used. The small particle size (nano particle) helps reduce this shine/shiny, but it still cannot compete with Chemical Sun Screen which does not cause shine/shiny.

Difference Between Titanium Dioxide and Zinc Oxide: Both Ingredients It acts to protect against UV light in different wavelengths. Titanium Dioxide can protect against short-wave UVA and both short- and long-wavelength UVB, while Zinc Oxide can protect against long-wave UVA well. In mixing sunscreen formulas Therefore, both ingredients should be used. Because it can cover UVA/UVB at all wavelengths completely.

The company sells 4 types of Zinc Oxide.

1. Zinc Oxide 200nm EasyDisperse™, 200nm powder, silicone coated. Makes it easy to spread into any sunscreen formula. Gives a soft feeling on the skin, adheres well to the skin, and gives low whiteness.

2. Zinc Oxide Micronized powder type, uncoated, suitable for use in formulas with disinfectant effects such as deodorant formulas. Not suitable for use in sunscreen. that requires high dispersion to achieve good sun protection performance

3. Zinc Oxide 35nm Liquid, liquid type , with a powder particle size of 35 nanometers, ready to be mixed in any sunscreen formula, easy to use, feels soft on the skin, adheres well to the skin, does not cause whiteness on the skin.

4. Zinc Oxide Nano EasyDisperse™ Powder type smaller than 200nm, coated with silicone. Makes it easy to spread into any sunscreen formula. Gives a soft feeling on the skin, adheres well to the skin, and gives the lowest whiteness.

Recommendations for choosing to use in various products

Sun protection products who want to focus on sun protection efficiency And there is no need to cause whiteness on the skin. It is an emulsion in an oil-in-water system using Zinc Oxide Nano EasyDisperse™.

Sun protection products who want to focus on sun protection efficiency And does not have to cause whiteness on the skin by being an emulsion in a water-in-oil system using Zinc Oxide 35nm Liquid, liquid type.

Sun protection products who want to claim that it is non-nano Zinc Oxide, choose Zinc Oxide 200nm EasyDisperse™

Diaper rash products, deodorant or deodorant/odorant, or disinfectant, choose Zinc Oxide Micronized.

Usage rate: 5-25% (use according to desired efficiency Please see how to calculate SPF and PA above.)

Appearance: White powder, light weight, particle size 200nm on average.

Mixing: For sunscreen, mix in Cyclomethicone silicone in a 1:1 ratio (please see mixing instructions below for details). For powder makeup. Can be mixed directly with other types of flour.

Storage: Store at room temperature. Avoid sunlight. Shelf life: 2 years.

INCI: Zinc Oxide (97%), Triethoxycaprylylsilane (3%)

Please see how to mix sunscreen here.

*Other types of Zinc Oxide have different SPF values. Therefore, this formula cannot be used to calculate.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |

Cart

No products