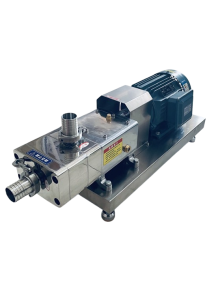

Screw Pump (2.2KW, SS304, 6CBM/hr)

- Product Code: 126108

Screw pump, or progressive cavity pump, is a type of positive displacement pump that uses a screw-like rotor to move fluid through a series of cavities formed by the stator. As the rotor turns, these cavities progress from the pump's inlet to its outlet, allowing a steady flow of fluid

Stainless 304 / GMP Approved

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

Screw pump, or progressive cavity pump, is a type of positive displacement pump that uses a screw-like rotor to move fluid through a series of cavities formed by the stator. As the rotor turns, these cavities progress from the pump's inlet to its outlet, allowing a steady flow of fluid. Screw pumps are valued for their ability to handle viscous or abrasive fluids, making them ideal for applications where traditional pumps might face clogging or wear.

Key Features and Benefits:

- Non-pulsating flow: Screw pumps offer a smooth, continuous flow, which is ideal for applications requiring stable pressure and minimal turbulence.

- Handling of high-viscosity fluids: They can manage thick fluids (e.g., oils, syrups, slurries), even those with suspended solids.

- Self-priming capability: This feature allows them to draw fluid into the pump without needing initial filling, ideal for conditions with variable fluid levels.

- Gentle handling of delicate materials: Useful in food, pharmaceuticals, and cosmetics where the integrity of the product is important.

Applications

- Food and beverage processing (e.g., syrups, sauces, mashed foods)

- Oil and gas industry (e.g., moving crude oil)

- Wastewater treatment (e.g., sludge handling)

- Cosmetic and pharmaceutical manufacturing (e.g., creams, lotions)

Screw pumps are versatile and efficient for specific scenarios where other pump types might struggle, particularly with high-viscosity or abrasive materials.

Be the first to review this product :-)

Recommend Lab-Service

| Lab Service | Price |

|---|

Screw pump, or progressive cavity pump, is a type of positive displacement pump that uses a screw-like rotor to move fluid through a series of cavities formed by the stator. As the rotor turns, these cavities progress from the pump's inlet to its outlet, allowing a steady flow of fluid

Stainless 304 / GMP Approved

Screw pump, or progressive cavity pump, is a type of positive displacement pump that uses a screw-like rotor to move fluid through a series of cavities formed by the stator. As the rotor turns, these cavities progress from the pump's inlet to its outlet, allowing a steady flow of fluid. Screw pumps are valued for their ability to handle viscous or abrasive fluids, making them ideal for applications where traditional pumps might face clogging or wear.

Key Features and Benefits:

- Non-pulsating flow: Screw pumps offer a smooth, continuous flow, which is ideal for applications requiring stable pressure and minimal turbulence.

- Handling of high-viscosity fluids: They can manage thick fluids (e.g., oils, syrups, slurries), even those with suspended solids.

- Self-priming capability: This feature allows them to draw fluid into the pump without needing initial filling, ideal for conditions with variable fluid levels.

- Gentle handling of delicate materials: Useful in food, pharmaceuticals, and cosmetics where the integrity of the product is important.

Applications

- Food and beverage processing (e.g., syrups, sauces, mashed foods)

- Oil and gas industry (e.g., moving crude oil)

- Wastewater treatment (e.g., sludge handling)

- Cosmetic and pharmaceutical manufacturing (e.g., creams, lotions)

Screw pumps are versatile and efficient for specific scenarios where other pump types might struggle, particularly with high-viscosity or abrasive materials.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |

Cart

No products