Desmodur N3300 (HDI)

- Product Code: 35860

a type of polyisocyanate hardener used primarily in the formulation of polyurethane coatings, adhesives, and sealants. It is a product from Covestro, a leading producer of high-performance polymers and materials

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

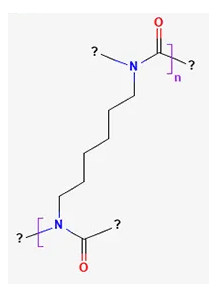

Desmodur N3300 is an aliphatic polyisocyanate hardener based on hexamethylene diisocyanate (HDI). Produced by Covestro, it is known for its excellent performance characteristics, particularly in applications requiring weather resistance, chemical resistance, and durability. Desmodur N3300 is widely used in high-performance polyurethane coatings, adhesives, and sealants.

Key Characteristics

-

Chemical Composition:

- Type: Aliphatic polyisocyanate based on HDI.

- NCO Content: Approximately 21.8% by weight.

- Viscosity: About 1200 mPa·s at 23°C.

- Equivalent Weight: Around 193 g/eq.

-

Properties:

- Weather Resistance: Outstanding resistance to UV radiation and weathering, making it ideal for outdoor applications.

- Chemical Resistance: High resistance to solvents, acids, and alkalis.

- Mechanical Properties: Provides coatings with excellent flexibility, hardness, and abrasion resistance.

- Durability: Long-lasting protection and maintains appearance over time.

Applications

-

Coatings:

- Automotive Coatings: Used in clear coats and topcoats for automotive finishes due to its high gloss and durability.

- Industrial Coatings: Suitable for protective coatings on metal, plastic, and wood surfaces exposed to harsh environments.

- Architectural Coatings: Employed in high-performance exterior paints and coatings that require long-term resistance to weathering.

- Marine Coatings: Provides protection for boats and ships against harsh marine conditions.

-

Adhesives and Sealants:

- Construction Adhesives: Provides strong bonding and long-lasting performance in construction materials.

- Sealants: Used in formulations requiring flexibility and resistance to environmental factors.

Advantages

- Performance: Superior weather and chemical resistance enhances the longevity and appearance of coatings.

- Durability: Maintains performance under harsh environmental conditions, providing long-lasting protection.

- Versatility: Can be used in a variety of formulations to meet specific application requirements.

- Aesthetic Quality: Produces high-gloss, clear, and durable finishes.

Disadvantages

- Cost: Typically more expensive than some other isocyanate hardeners.

- Handling Requirements: Requires careful handling and proper safety measures due to the reactive nature of isocyanates.

Handling and Safety

-

Personal Protective Equipment (PPE):

- Use appropriate PPE, including gloves, goggles, and protective clothing, to avoid skin and eye contact.

- Ensure the use of respirators or adequate ventilation to avoid inhalation of vapors.

-

Storage:

- Store in tightly closed containers in a cool, dry place away from moisture and sources of ignition.

- Protect from temperatures below 0°C and above 30°C to maintain product stability.

-

Safety Measures:

- Follow all safety data sheet (SDS) recommendations for safe handling and disposal.

- Use in well-ventilated areas to prevent the buildup of vapors.

Be the first to review this product :-)

Recommend Lab-Service

| Lab Service | Price |

|---|

a type of polyisocyanate hardener used primarily in the formulation of polyurethane coatings, adhesives, and sealants. It is a product from Covestro, a leading producer of high-performance polymers and materials

Desmodur N3300 is an aliphatic polyisocyanate hardener based on hexamethylene diisocyanate (HDI). Produced by Covestro, it is known for its excellent performance characteristics, particularly in applications requiring weather resistance, chemical resistance, and durability. Desmodur N3300 is widely used in high-performance polyurethane coatings, adhesives, and sealants.

Key Characteristics

-

Chemical Composition:

- Type: Aliphatic polyisocyanate based on HDI.

- NCO Content: Approximately 21.8% by weight.

- Viscosity: About 1200 mPa·s at 23°C.

- Equivalent Weight: Around 193 g/eq.

-

Properties:

- Weather Resistance: Outstanding resistance to UV radiation and weathering, making it ideal for outdoor applications.

- Chemical Resistance: High resistance to solvents, acids, and alkalis.

- Mechanical Properties: Provides coatings with excellent flexibility, hardness, and abrasion resistance.

- Durability: Long-lasting protection and maintains appearance over time.

Applications

-

Coatings:

- Automotive Coatings: Used in clear coats and topcoats for automotive finishes due to its high gloss and durability.

- Industrial Coatings: Suitable for protective coatings on metal, plastic, and wood surfaces exposed to harsh environments.

- Architectural Coatings: Employed in high-performance exterior paints and coatings that require long-term resistance to weathering.

- Marine Coatings: Provides protection for boats and ships against harsh marine conditions.

-

Adhesives and Sealants:

- Construction Adhesives: Provides strong bonding and long-lasting performance in construction materials.

- Sealants: Used in formulations requiring flexibility and resistance to environmental factors.

Advantages

- Performance: Superior weather and chemical resistance enhances the longevity and appearance of coatings.

- Durability: Maintains performance under harsh environmental conditions, providing long-lasting protection.

- Versatility: Can be used in a variety of formulations to meet specific application requirements.

- Aesthetic Quality: Produces high-gloss, clear, and durable finishes.

Disadvantages

- Cost: Typically more expensive than some other isocyanate hardeners.

- Handling Requirements: Requires careful handling and proper safety measures due to the reactive nature of isocyanates.

Handling and Safety

-

Personal Protective Equipment (PPE):

- Use appropriate PPE, including gloves, goggles, and protective clothing, to avoid skin and eye contact.

- Ensure the use of respirators or adequate ventilation to avoid inhalation of vapors.

-

Storage:

- Store in tightly closed containers in a cool, dry place away from moisture and sources of ignition.

- Protect from temperatures below 0°C and above 30°C to maintain product stability.

-

Safety Measures:

- Follow all safety data sheet (SDS) recommendations for safe handling and disposal.

- Use in well-ventilated areas to prevent the buildup of vapors.

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |

Cart

No products