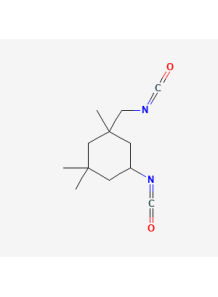

Isophorone diisocyanate (IPDI)

- Product Code: 126534

an aliphatic diisocyanate widely used in the production of polyurethane materials. It is valued for its ability to enhance the durability, flexibility, and chemical resistance of coatings, adhesives, elastomers, and sealants

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

- -

| Test Name | Specification |

|---|---|

| Appearance | Clear liquid |

| Chromatic Number (APHA) | ≤30 |

| IPDI Purity (% A/A) | ≥99.50 |

| NCO Content (% m/m) | ≥37.50 |

| Hydrolysable Chlorides (%) | ≤0.0200 |

| Chlorine Content (%) | ≤0.0400 |

Isophorone diisocyanate (IPDI) is an aliphatic diisocyanate widely used in the production of polyurethane materials. It is valued for its ability to enhance the durability, flexibility, and chemical resistance of coatings, adhesives, elastomers, and sealants.

Key Characteristics:

- Chemical Formula: C12H18N2O2

- Molecular Weight: 222.29 g/mol

- Appearance: Clear to slightly yellow liquid.

- Boiling Point: Approximately 158°C (at 0.5 mmHg).

- Reactivity: Reacts with compounds containing active hydrogens, such as alcohols, amines, and water, to form polyurethanes or ureas.

Applications:

-

Coatings:

- Used in industrial and automotive coatings.

- Offers excellent UV resistance and weatherability.

- Produces non-yellowing polyurethane finishes.

-

Adhesives:

- Enhances bonding strength and flexibility in adhesives.

- Provides resistance to environmental conditions.

-

Elastomers:

- Used in the production of flexible and durable elastomers for industrial applications.

-

Sealants:

- Provides chemical and mechanical stability to sealants, particularly for outdoor use.

Advantages of IPDI:

- Improved UV stability compared to aromatic diisocyanates.

- Better resistance to discoloration.

- Long-lasting performance in demanding environmental conditions.

Handling and Safety:

- Toxicity: IPDI is a hazardous chemical and requires proper handling to prevent inhalation, skin contact, or eye exposure.

- Protective Measures: Use appropriate personal protective equipment (PPE) such as gloves, goggles, and respiratory protection when working with IPDI.

- Storage: Store in a cool, dry, and well-ventilated area away from moisture and incompatible materials.

Environmental and Regulatory Notes:

- IPDI is subject to regulatory oversight for workplace exposure due to its potential health effects.

- Environmental release should be controlled as it can contribute to air and water pollution.

Let me know if you need more detailed information on its synthesis, specific formulations, or handling protocols!

Be the first to review this product :-)

Recommend Lab-Service

| Lab Service | Price |

|---|

an aliphatic diisocyanate widely used in the production of polyurethane materials. It is valued for its ability to enhance the durability, flexibility, and chemical resistance of coatings, adhesives, elastomers, and sealants

Isophorone diisocyanate (IPDI) is an aliphatic diisocyanate widely used in the production of polyurethane materials. It is valued for its ability to enhance the durability, flexibility, and chemical resistance of coatings, adhesives, elastomers, and sealants.

Key Characteristics:

- Chemical Formula: C12H18N2O2

- Molecular Weight: 222.29 g/mol

- Appearance: Clear to slightly yellow liquid.

- Boiling Point: Approximately 158°C (at 0.5 mmHg).

- Reactivity: Reacts with compounds containing active hydrogens, such as alcohols, amines, and water, to form polyurethanes or ureas.

Applications:

-

Coatings:

- Used in industrial and automotive coatings.

- Offers excellent UV resistance and weatherability.

- Produces non-yellowing polyurethane finishes.

-

Adhesives:

- Enhances bonding strength and flexibility in adhesives.

- Provides resistance to environmental conditions.

-

Elastomers:

- Used in the production of flexible and durable elastomers for industrial applications.

-

Sealants:

- Provides chemical and mechanical stability to sealants, particularly for outdoor use.

Advantages of IPDI:

- Improved UV stability compared to aromatic diisocyanates.

- Better resistance to discoloration.

- Long-lasting performance in demanding environmental conditions.

Handling and Safety:

- Toxicity: IPDI is a hazardous chemical and requires proper handling to prevent inhalation, skin contact, or eye exposure.

- Protective Measures: Use appropriate personal protective equipment (PPE) such as gloves, goggles, and respiratory protection when working with IPDI.

- Storage: Store in a cool, dry, and well-ventilated area away from moisture and incompatible materials.

Environmental and Regulatory Notes:

- IPDI is subject to regulatory oversight for workplace exposure due to its potential health effects.

- Environmental release should be controlled as it can contribute to air and water pollution.

Let me know if you need more detailed information on its synthesis, specific formulations, or handling protocols!

| Mechanism | - |

| Appearance | - |

| Longevity | - |

| Strength | - |

| Storage | - |

| Shelf Life | - |

| Allergen(s) | - |

| Dosage (Range) | - |

| Recommended Dosage | - |

| Dosage (Per Day) | - |

| Recommended Dosage (Per Day) | - |

| Mix Method | - |

| Heat Resistance | - |

| Stable in pH range | - |

| Solubility | - |

| Product Types | - |

| INCI | - |

Cart

No products